Industry knowledge

The production steps of 19MM 99.99% teflon tape

Material Preparation: The primary material used in PTFE tape is polytetrafluoroethylene (PTFE) resin. The raw PTFE material is obtained and prepared for the production process.

Mixing and Extrusion: The PTFE resin is mixed with any required additives or fillers to enhance its properties, if applicable. The mixture is then fed into an extruder, where heat and pressure are applied to melt the PTFE and shape it into a continuous strip of tape. The extrusion process ensures that the tape has a consistent thickness and width.

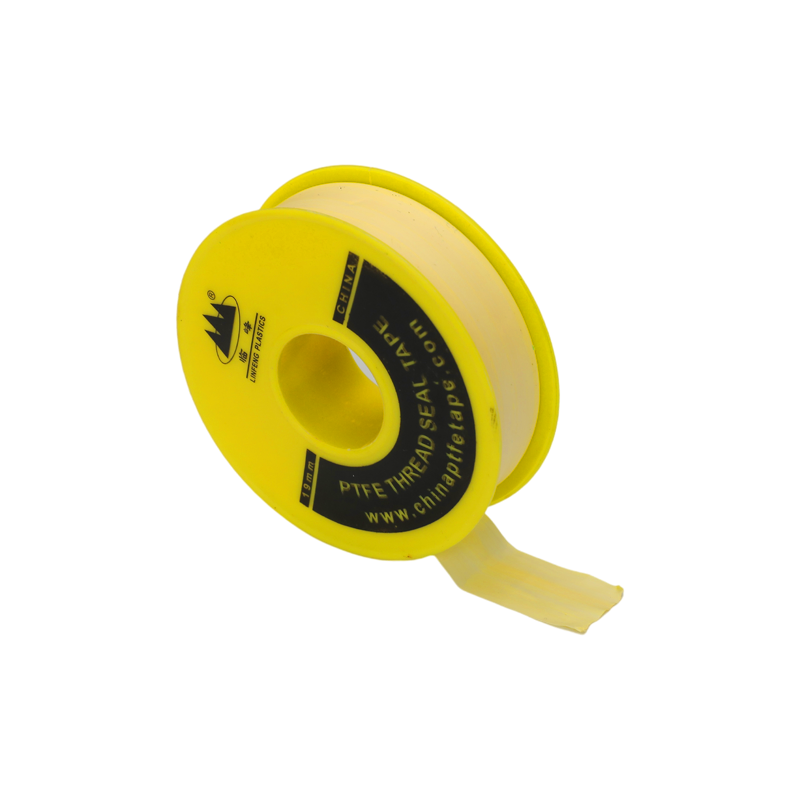

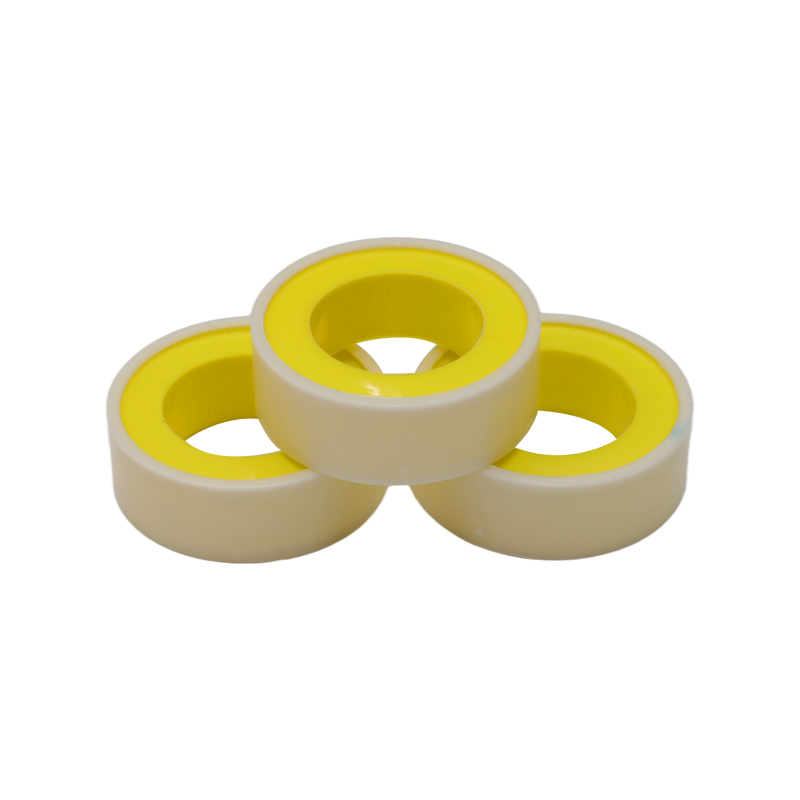

Cooling and Cutting: As the PTFE tape emerges from the extruder, it is rapidly cooled to solidify it. The cooled tape is then cut into the desired length, typically wound onto spools or cut into individual rolls.

Quality Control: Before packaging, the 19mm PTFE tape undergoes quality control inspections to ensure that it meets the required standards and specifications. This step involves checking for proper thickness, width, uniformity, purity, and any other relevant quality parameters.

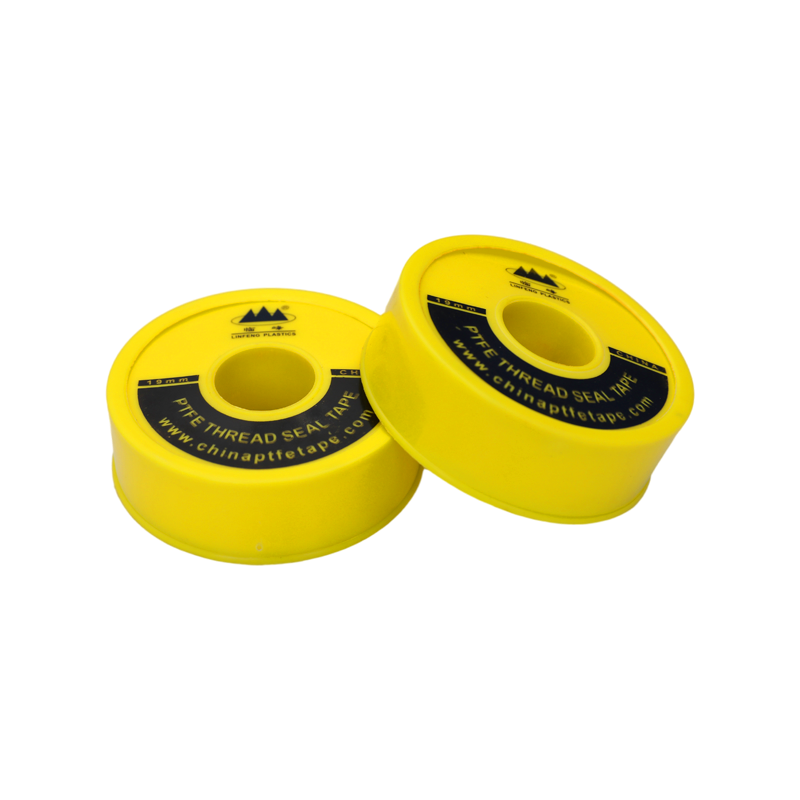

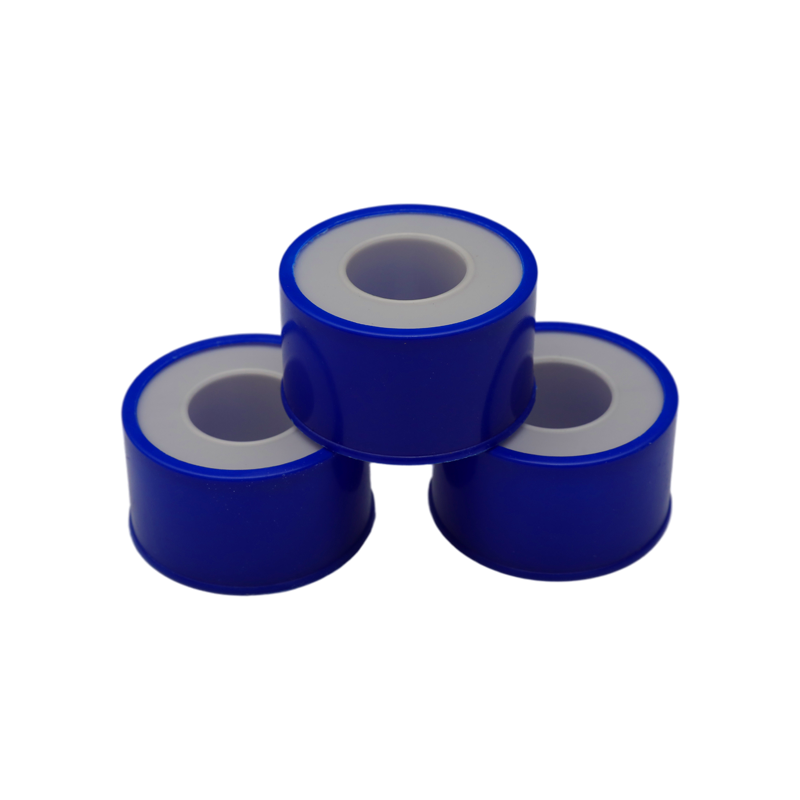

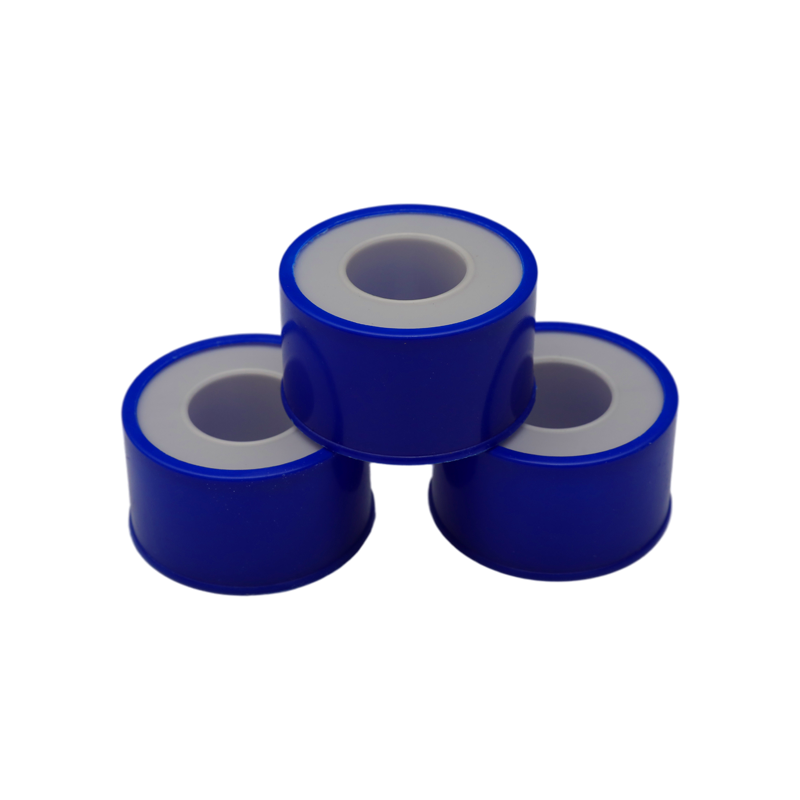

Packaging: The 19mm PTFE tape is packaged for distribution and sale. It is usually wound onto spools, placed in individual plastic bags, or wrapped in protective packaging to maintain its quality and prevent damage during transportation and storage.

Labeling and Documentation: Labels or stickers with product information, specifications, safety warnings, and other relevant details are affixed to the packaging. Documentation such as batch numbers, manufacturing dates, and certifications may also be included.

Storage and Distribution: The packaged 19mm PTFE tape is stored in a suitable warehouse or distribution center until it is ready for shipment. It is then distributed to retailers, wholesalers, or directly to customers.

English

English Espa?ol

Espa?ol