Industry knowledge

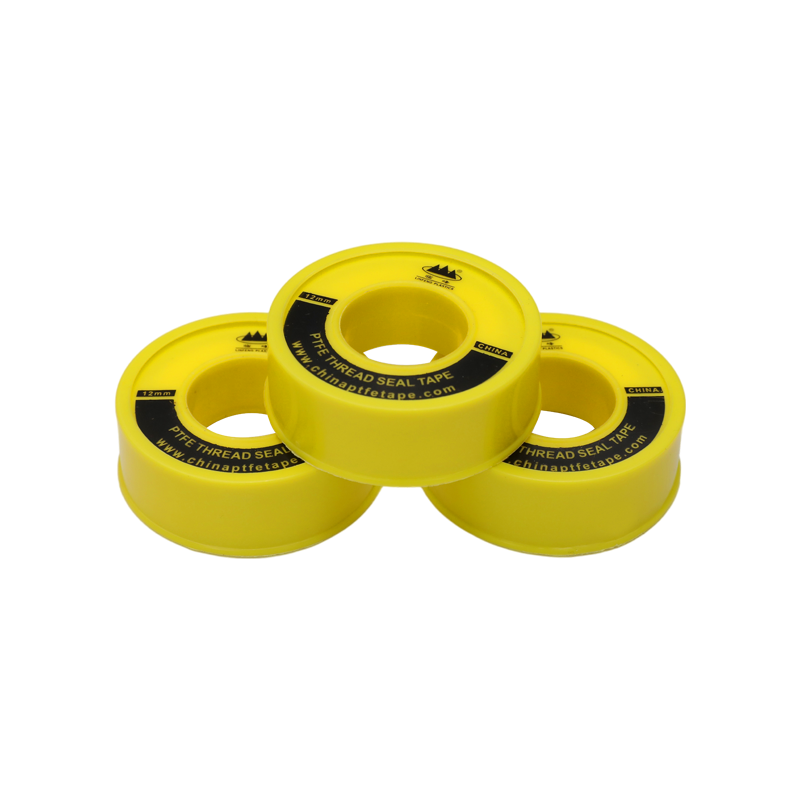

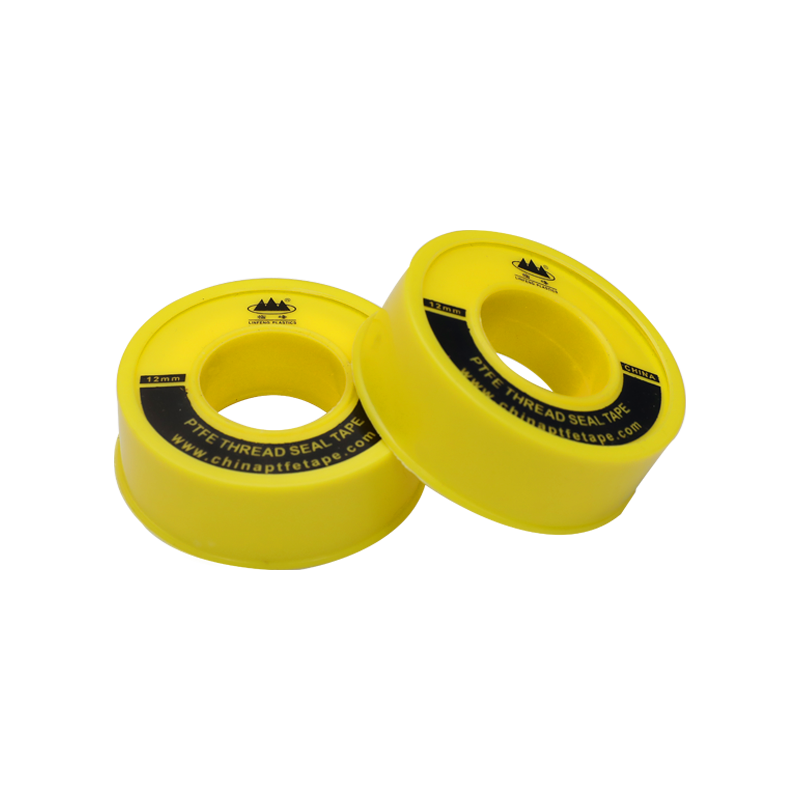

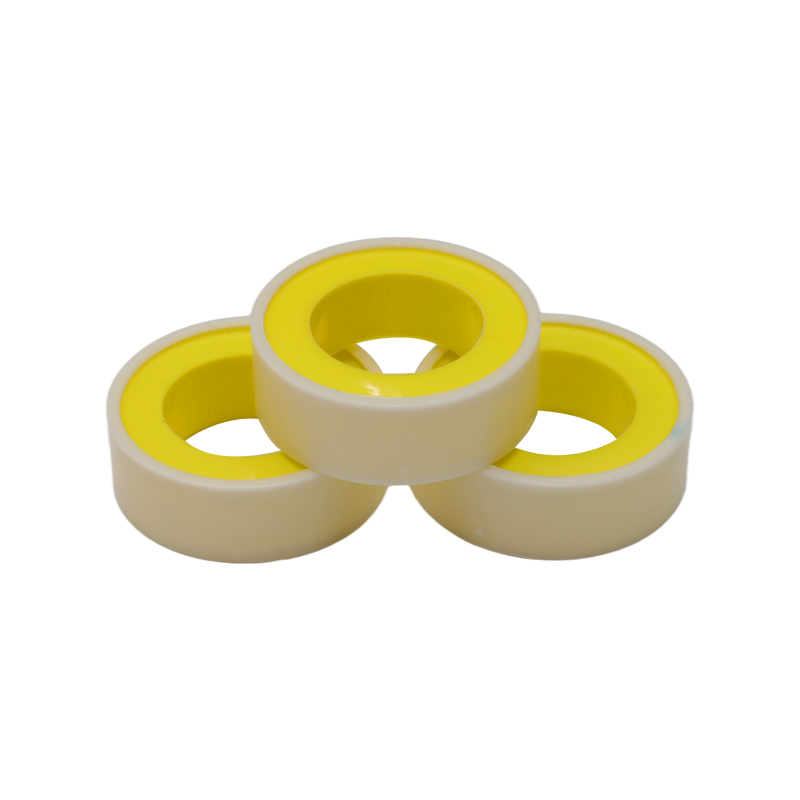

The Importance of 12MM yellow ptfe tape

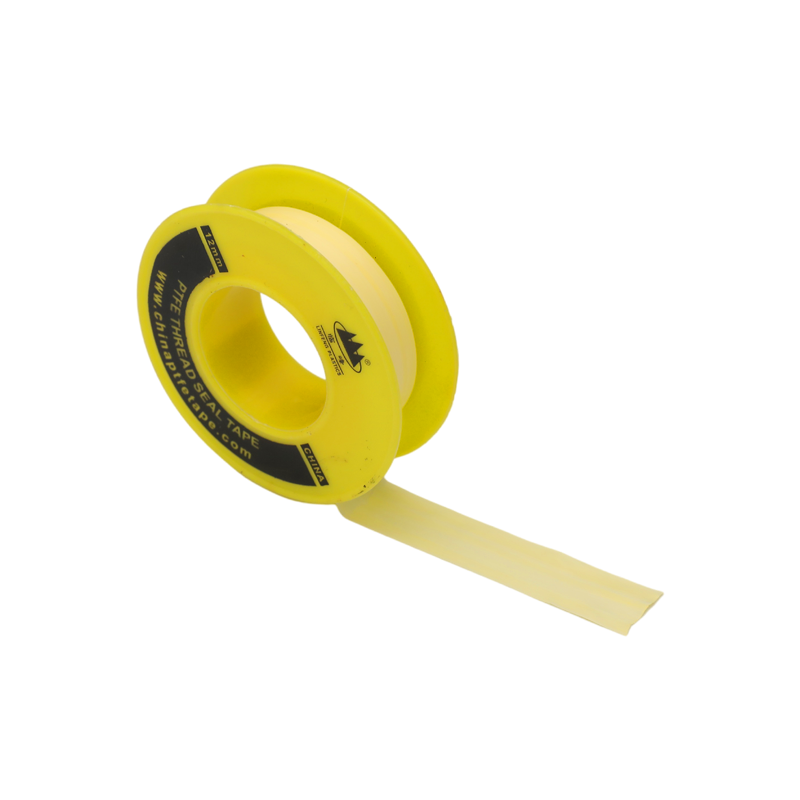

12mm yellow PTFE (polytetrafluoroethylene) tape, also known as high-density PTFE tape or premium grade PTFE tape, holds significance in certain applications due to its specific characteristics and properties. Here are some key reasons for the importance of 12mm yellow PTFE tape:

Increased Density and Thickness: Yellow PTFE tape is typically denser and thicker compared to standard white PTFE tape. The higher density and thickness provide enhanced sealing capabilities, making it suitable for applications with higher pressure or more demanding conditions.

Higher Temperature Resistance: Yellow PTFE tape is designed to withstand higher temperatures than standard PTFE tape. It has a higher maximum temperature rating, typically up to 260°C (500°F) or higher, making it suitable for applications involving high-temperature fluids, steam, or other hot substances.

Chemical Compatibility: PTFE tape, including the yellow variant, exhibits excellent chemical resistance. It is resistant to a wide range of chemicals, acids, and solvents, making it suitable for applications involving corrosive fluids or chemical processes.

Reliable Sealing Performance: The denser and thicker construction of yellow PTFE tape provides a reliable and effective seal on threaded connections. It helps prevent leaks, ensuring a tight and secure joint between pipe fittings, valves, or other threaded components.

Visual Differentiation: The yellow color of the tape serves as a visual identifier, distinguishing it from standard white PTFE tape. This can be useful in specific applications where it is necessary to differentiate between different types of tape or ensure compliance with specific industry requirements.

Specialized Applications: Yellow PTFE tape finds particular importance in industries such as oil and gas, chemical processing, refineries, and other industrial settings where the sealing tape needs to withstand harsher conditions, higher pressures, or elevated temperatures.

English

English Espa?ol

Espa?ol