-

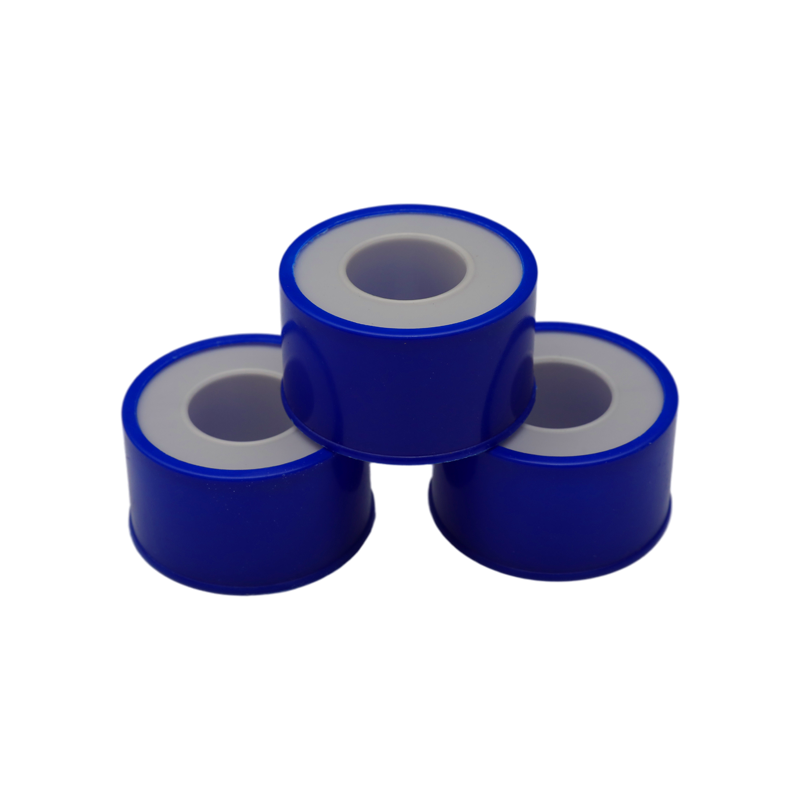

The Unsung Hero of Plumbing: Water Pipe Teflon Tape

Apr 30 , 2024

When it comes to plumbing, there's a small but mighty tool that often goes unnoticed—the water pipe ...

-

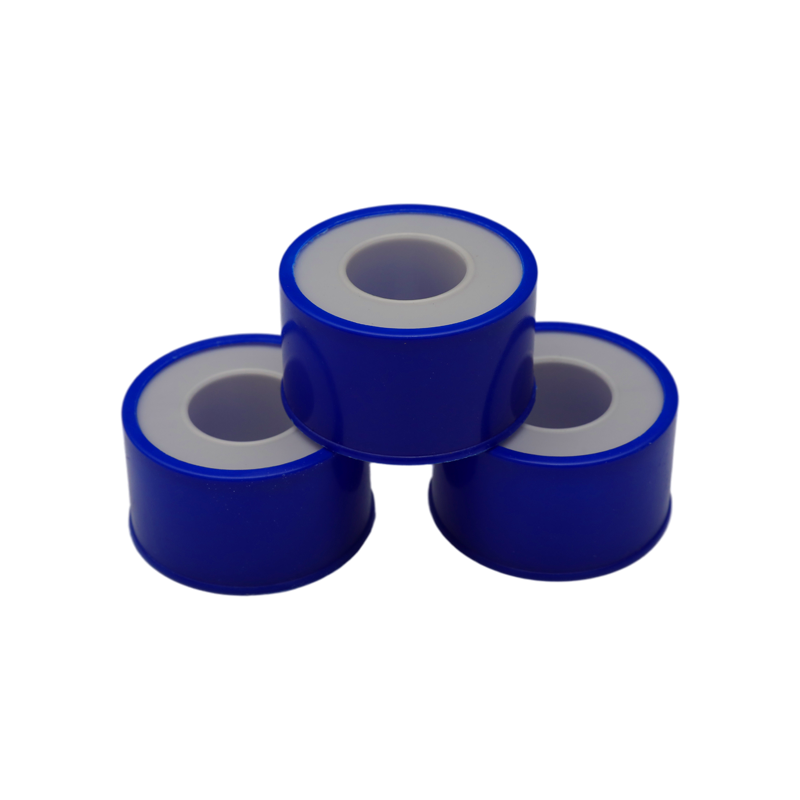

Unleash the Power of Waterproof Ptfe Teflon Tape

Apr 25 , 2024

Are you tired of dealing with leaky pipes and fittings? Look no further than waterproof ptfe teflon ...

-

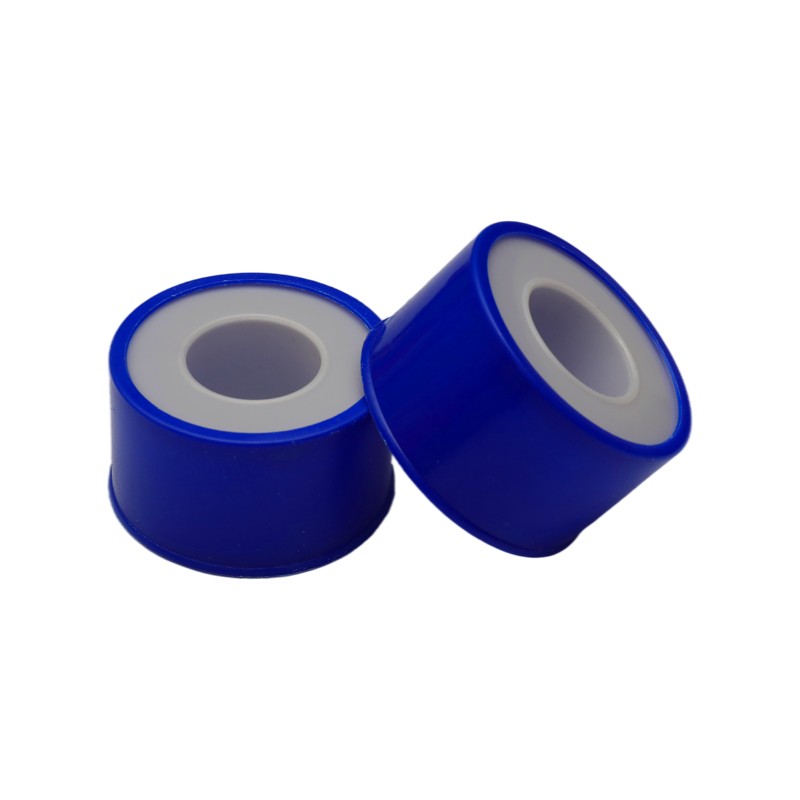

Explore the magical uses of 15MM teflon tape

Apr 15 , 2024

You may have heard of 15MM teflon tape, perhaps using it in home repair or industrial applications. ...

-

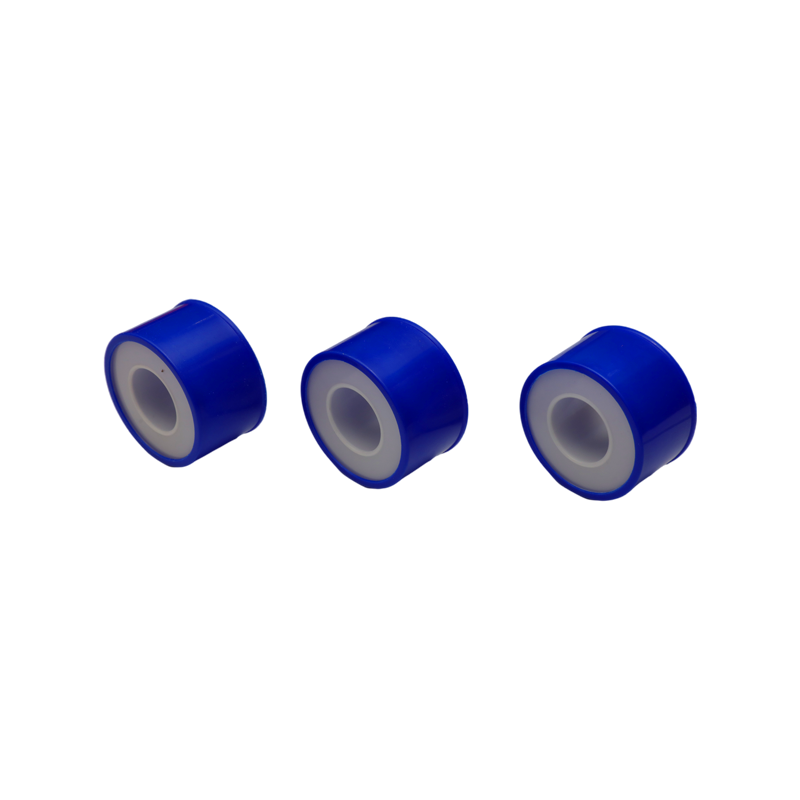

Comprehensive guide about 12MM Teflon Tape

Apr 12 , 2024

When it comes to plumbing, a small yet mighty tool that often goes unnoticed is the 12MM Teflon tape...

-

Will 19MM Teflon tape release harmful gases during use?

Apr 02 , 2024

19MM Teflon tape will not release harmful gases during normal use. Teflon tape is usually made of po...

-

What are the surface properties of this Teflon tape? And does the material adhere easily?

Mar 25 , 2024

The surface properties of 19mm Teflon tape are mainly reflected in its very smooth and non-stick cha...

-

Will harmful substances be released during the use of 19MM Teflon tape?

Mar 19 , 2024

No harmful substances are released when using 19mm Teflon tape. Teflon tape is typically made from p...

-

What is non-reactive in 12MM Teflon Tape?

Mar 13 , 2024

Teflon tape, also known as PTFE (polytetrafluoroethylene) tape, is chemically inert and does not und...

-

Unveiling the Power of PTFE Sealing Tape in Everyday Applications

Mar 08 , 2024

In the intricate world of sealing solutions, there exists a hero often unnoticed yet indispensable i...

-

What effect does using nanostructures have on 19MM Teflon Tape?

Feb 26 , 2024

Using nanostructures on 19mm Teflon tape, or PTFE tape, can have several effects on its properties a...

-

What are the benefits of introducing micro-texture or pattern to 19MM Teflon Tape?

Feb 22 , 2024

Introducing micro-texture or patterns to 19mm Teflon tape, or PTFE tape, can offer several benefits,...

-

How to improve the low friction coefficient of 19MM Teflon Tape?

Feb 18 , 2024

Improving the low friction coefficient of 19mm Teflon tape, or PTFE tape, typically involves enhanci...

Industry knowledge

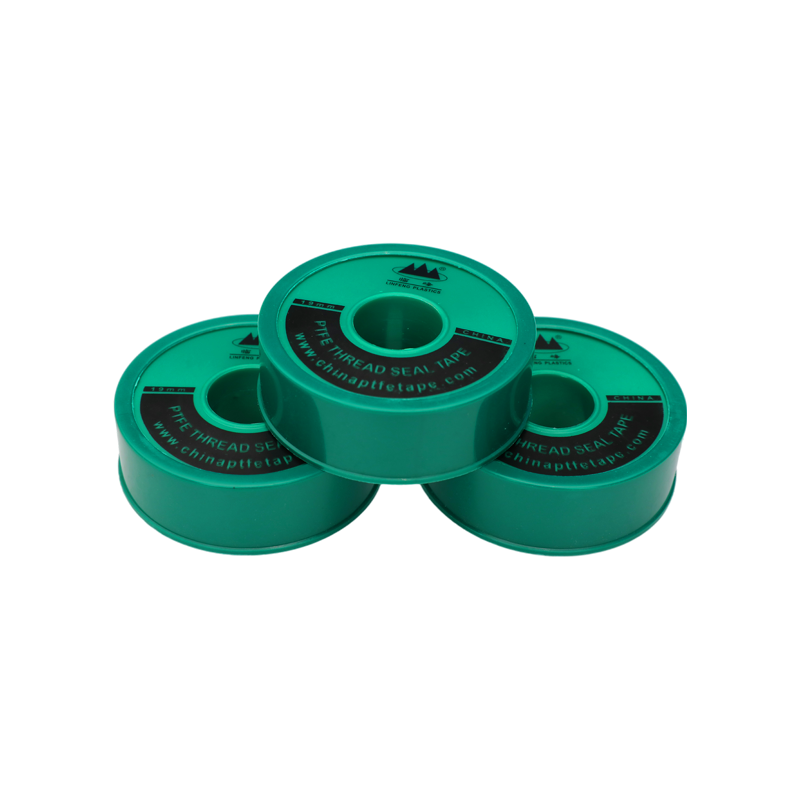

The difference of 25MM with high density ptfe tape and 19MM ptfe thread tape

The difference between

25mm high-density PTFE tape and 19mm PTFE thread tape lies in their width, density, and intended applications. Here are the primary distinctions between these two types of PTFE tapes:

Width:

25mm High-Density PTFE Tape: This tape has a width of 25mm, which is wider compared to the standard 19mm PTFE thread tape.

19mm PTFE Thread Tape: This tape has a width of 19mm, which is the common standard width for PTFE thread tapes.

The difference in width is primarily related to the size of the pipe or fitting being sealed. The wider tape allows for better coverage and sealing on larger diameter pipes and fittings.

Density:

25mm High-Density PTFE Tape: This tape is referred to as "high-density" PTFE tape, indicating a higher density compared to standard PTFE thread tape. The high-density construction typically results in a thicker tape with more material per unit area, making it denser and potentially more robust.

19mm PTFE Thread Tape: This tape refers to the standard PTFE thread tape, which has a lower density compared to high-density PTFE tape. The standard density tape is thinner and may have a lower mass per unit area.

The difference in density can affect the tape's sealing properties, tensile strength, and overall durability.

Intended Applications:

25mm High-Density PTFE Tape: The high-density PTFE tape, with its wider width and potentially higher density, is commonly used in industrial applications that require a more robust sealing solution. It can be suitable for larger pipes, heavy-duty fittings, or applications where higher pressures or extreme conditions are involved.

19mm PTFE Thread Tape: The standard 19mm PTFE thread tape is widely used in plumbing applications for sealing threaded pipe connections. It is commonly used in residential and commercial plumbing systems for water supply lines, faucets, showers, and other similar applications.

While both tapes are PTFE-based and share similar properties such as chemical resistance and non-stick characteristics, the difference in width and density makes them better suited for specific applications based on the pipe size, sealing requirements, and environmental factors.

English

English Espa?ol

Espa?ol