What are the key properties of 12mm Teflon tape?

12mm Teflon tape, also known as PTFE tape (Polytetrafluoroethylene tape), possesses several key properties that make it a popular choice for sealing threaded pipe connections. Here are some of its essential properties:

Chemical Resistance: Teflon tape is highly resistant to a wide range of chemicals. This property makes it suitable for use in various industrial applications where exposure to corrosive substances is a concern.

Temperature Resistance: 12mm Teflon tape has a high-temperature tolerance, typically ranging from -200°C to 260°C (-328°F to 500°F). This makes it suitable for applications where extreme temperatures are encountered.

Non-Stick Properties: Teflon is known for its non-stick or low-friction properties. This characteristic is beneficial when working with threaded connections, as it allows for easier assembly and disassembly without damaging the tape or the threads.

Sealing Ability: The primary function of 12mm Teflon tape is to act as a thread sealant. It creates a tight seal between threaded pipe joints, helping to prevent leaks. Properly applied Teflon tape provides an effective barrier against fluid or gas leakage in the connection.

Electrical Insulation: Teflon is an excellent electrical insulator. This property makes Teflon tape suitable for applications where electrical insulation is required, such as in certain types of wiring and connections.

Flexibility: Teflon tape is flexible and can conform to the threads of different pipe fittings. This flexibility allows for easy application and ensures a snug fit around the threads.

Compatibility with Various Materials: 12mm Teflon tape is compatible with a variety of materials commonly used in plumbing and industrial applications, including metals and plastics. It can be used with pipes made of materials like copper, brass, stainless steel, and PVC.

Resistance to Aging and Weathering: Teflon tape exhibits resistance to aging and weathering, contributing to its long-lasting performance in various environmental conditions.

Inertness: Teflon is chemically inert, meaning it does not react with most substances. This inertness is advantageous in applications where the material must not contaminate or react with the substances being transported through the pipes.

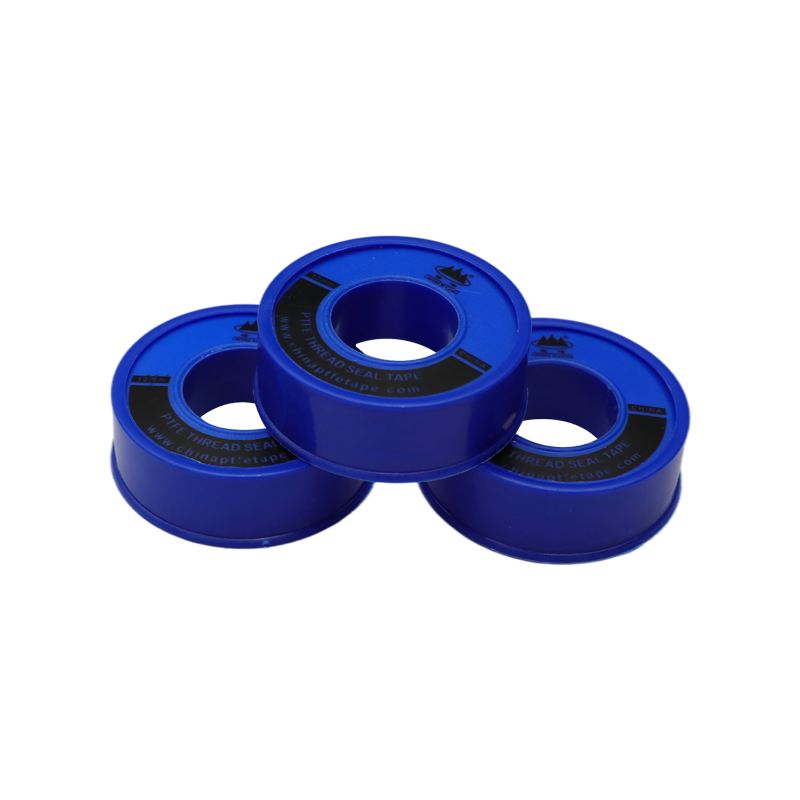

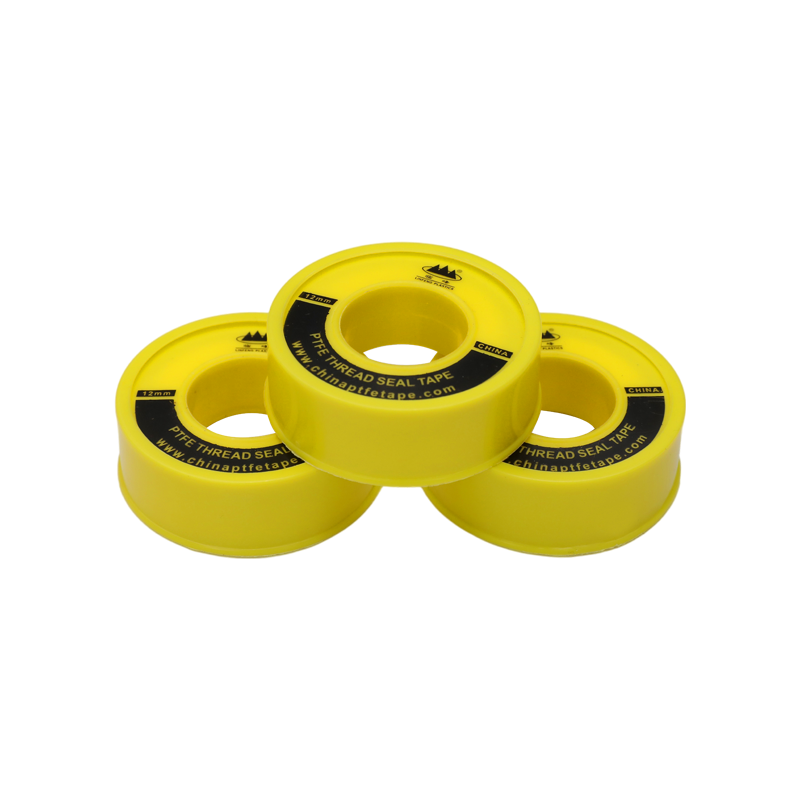

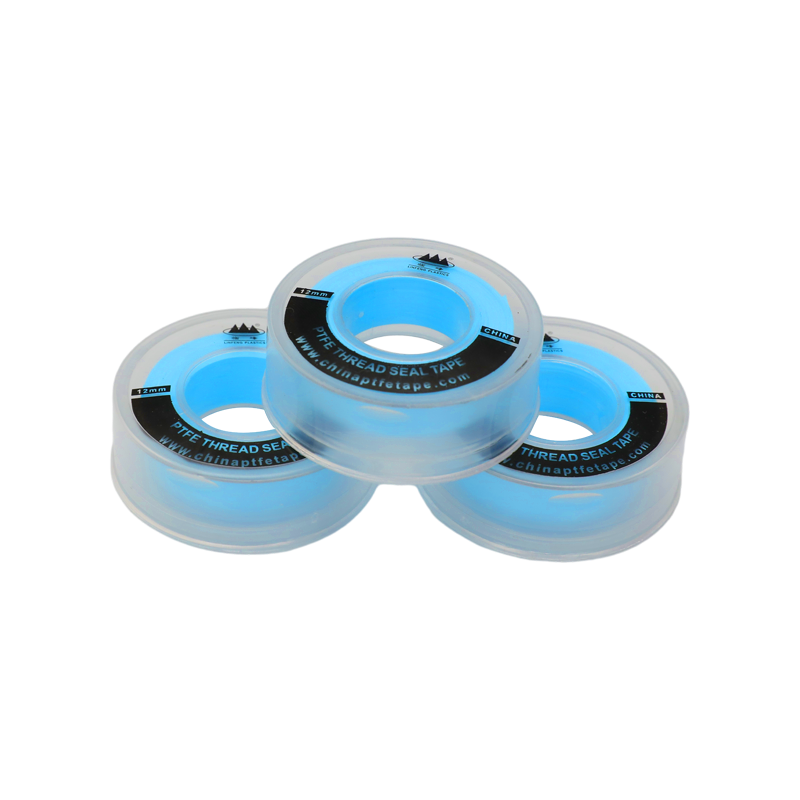

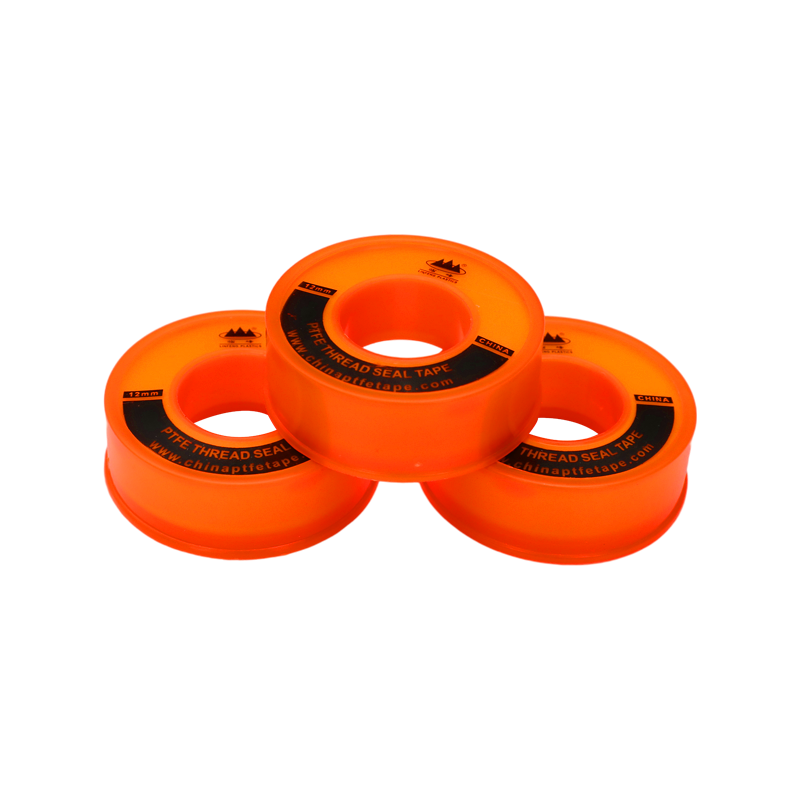

Easy Application: Applying 12mm Teflon tape is a straightforward process. It is commonly available in rolls, and users can easily wrap it around the threads of pipe fittings.

It's important to note that the specific properties of Teflon tape can vary between different brands and formulations. Always follow the manufacturer's recommendations and guidelines for the proper use of the specific Teflon tape product you are working with.

How do you apply 12mm Teflon tape correctly?

Applying

12mm Teflon tape correctly is crucial to ensure a proper seal and prevent leaks in threaded pipe connections. Here's a step-by-step guide on how to apply Teflon tape:

Prepare the Threads:

Make sure the threads on both the male and female pipe fittings are clean and free of dirt, debris, or old tape.

Choose the Right Tape:

Select a high-quality 12mm Teflon tape suitable for the intended application. Ensure that the tape is compatible with the type of pipes and the substances being transported.

Start at the End:

Begin wrapping the Teflon tape around the threads of the male pipe fitting. Start at the end of the threads and wrap in the direction of the threads.

Wrap Clockwise:

Wrap the tape clockwise around the threads. This ensures that, when the male and female threads are joined, the tape tightens rather than unravels.

Maintain Tension:

Maintain tension on the tape as you wrap it around the threads. Stretch the tape slightly to ensure a snug fit. This helps create a uniform and effective seal.

Overlap Slightly:

Overlap the tape slightly with each wrap to ensure complete coverage of the threads. A 50% overlap is a common recommendation.

Number of Wraps:

Generally, 3 to 5 wraps are sufficient for most applications. However, the number of wraps may vary depending on the specific requirements and the thickness of the tape.

Avoid Excess Tape:

Avoid using excessive amounts of tape, as this can lead to over-tightening and potential tape shredding. A moderate amount of tape ensures a proper seal without compromising the integrity of the connection.

Smooth the Tape:

After wrapping, use your fingers to smooth the tape down on the threads. This helps to secure the tape in place and ensures a tight seal.

Trim the End:

Once you have completed the wrapping, tear or cut the tape neatly to finish at the end of the threads. Avoid leaving loose tape that could interfere with the connection.

Assemble the Connection:

Assemble the male and female pipe fittings promptly after applying the Teflon tape. Tighten the connection securely but avoid over-tightening, as this may lead to tape shredding.

Check for Leaks:

After assembly, check for any signs of leaks. If leaks are detected, disassemble the connection, inspect the tape, and reapply if necessary.

English

English Espa?ol

Espa?ol